𝐏𝐋𝐀𝐍𝐓𝟐𝐅𝐎𝐎𝐃 𝐇𝐀𝐒 𝐅𝐔𝐍𝐃𝐄𝐃 𝐀 𝐍𝐄𝐖 𝐏𝐑𝐎𝐉𝐄𝐂𝐓! 🌟

It is with great pleasure that we can now announce that Plant2Food has funded the exciting project `𝗣𝗿𝗼𝗣𝘂𝗹𝘀𝗲´ from the 2023 call round. You can read more about the project below - and follow the projects progress and result at their own site under the tap `Funded projects´(or click on the picture below).

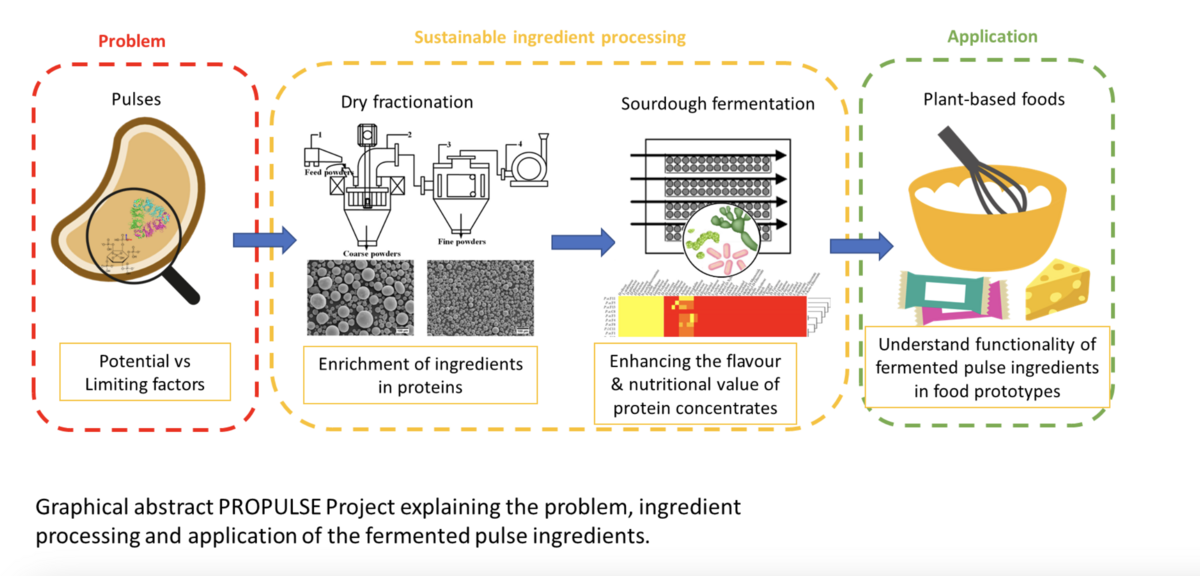

ProPulse: A novel sustainable PROcessing route to produce nutritious PULSE ingredients free of off-flavours

The ProPulse projects aims to develop a sustainable processing approach for production of clean label and functional protein-rich pulse ingredients to be used in the production of emulsions such as plant-based yogurt and cheese.

The background for the project

Pulse ingredients are increasingly incorporated in various foods to add nutritional value and improve texture). Traditionally, pulse protein concentrates and isolates are prepared by wet processing, which is extremely energy intensive. Dry fractionation (DF) has huge potential for sustainable production of mildly refined pulse protein concentrates, but despite high enrichment factors and good functionality, these concentrates still retain a beany off-flavour and often have high contents of antinutritional factors (ANFs). These factors limit the application of otherwise sustainably produced ingredients in food applications. A promising way to unlock the full potential for dry-enriched protein concentrates is to carry out a sourdough fermentation (SDF), which is a well-known natural process for preparing foods by fermentation with bacteria offering numerous health benefits. For processing pulse ingredients, SDF specifically offers the possibility to (i) remove or even add flavours, (ii) reduce ANFs in a natural way, and (iii) enrich the ingredients in micronutrients (Fig. 1). Hitherto this technique is not often applied, which is related to the unavailability of plant-specific starter cultures and limited knowledge about the underlying mechanisms for strain selection and required conditions to steer towards fermented pulse-ingredients with desired properties and technofunctional behaviour.

The activities and outcome

Therefore, the project PROPULSE will investigate

1) Development of plant-based specific starter cultures via selection and improvement using adaptive laboratory evolution (ALE) regimes,

2) The new SDF technology to sustainably process functional pulse-protein ingredients, and

3) Understand the potential of sourdough-based pulse ingredients for designing high-quality emulsion-based model foods.

Hereby, PROPULSE aims to develop a sustainable processing approach for production of clean label and functional protein-rich pulse ingredients to be used in the production of emulsions such as plant-based yogurt and cheese.(Fig. downfor).

The consortium consists of Wageningen University & Research, University of Copenhagen and a mix of larger (3) and smaller (5) companies and one non-profit society, each contributing with their unique expertise to the project ambitions. Next to peer-reviewed publications, the project will openly share results and actively disseminate generated knowledge in workshops and via social media.