Better mimicking of the natural environment of cells in plastic culture wells

The CELPPLUS project was funded in the ODIN pilot (2020-2023). The team used nanotechnological approaches to develop new plastic culture wells that better mimic the natural microenvironment of cells.

If you have kids, then you probably know that they almost always behave better when they are not at home. You’ve probably spent quite some time wondering why this is - and you’ve come to the same conclusion as all other parents: Their behavior is dependent on their environment. This is also the case for cells.

The complex behavior of cells

Knowledge about how cells behave is important, especially with regard to drug discovery.

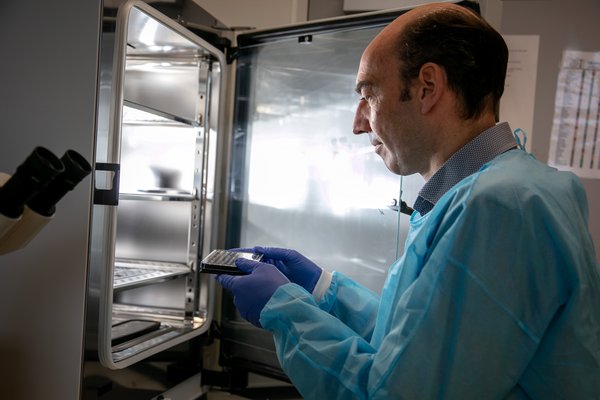

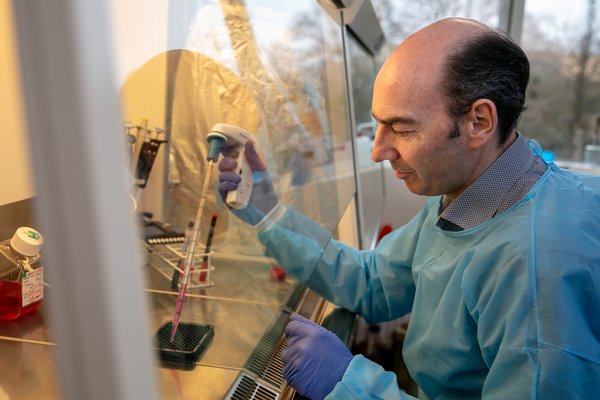

“We have advanced techniques for characterizing cells, when we for example, test their response to potential drugs. The problem is, however, that the cells are taken from their natural environment and placed in plastic culture wells in the lab. They don’t like this,” says Duncan Sutherland, head of the CELPPLUS project, and explains why: “Cells are social. Inside the body, they interact with each other and their surroundings all the time and they receive a lot of signals that tell them how to behave. As soon as you remove them from the body, the signals changes and so does their behavior.”

In the drug discovery pipeline, testing is an essential step. No drugs are allowed to go into clinical trials before they have been thoroughly tested. But many drugs are tested in the lab on cells that have a significantly different behavior than they would in the body. This means that researchers can’t compare the response to a given drug between cells in the body and cells in a culture well.

“There is a huge difference between in vivo and in vitro. Currently, the in vitro culture wells in the laboratory only take into account the soluble signals that cells receive. There is no mimicking of the adhesive signals, which the cells receive in vivo in the body,” states Duncan Sutherland.

In practice, this entails that many drugs tested in culture wells, fail clinical trials. This has both economical and personal consequences for patients, who must wait longer for new and better drugs and they must also pay more because the drug discovery process is costly with many failed drug candidates.

How to make cells behave naturally

The focus of the CELPPLUS project is to make cells feel more at home in the plastic culture wells used in the laboratory. Therefore, Duncan Sutherland decided to use his expertise within physics and nanotechnology to develop plates with 96 cell culture wells that better mimic the in vivo microenvironment of cells in a controlled manner. “The goal of our project is to develop an assay that gives more realistic results in drug candidate testing. This will help reduce the failure rate of drugs in clinical trials,” he explains. The CELPPLUS team is trying to make the cells feel at home and thereby make them behave naturally.

The CELPPLUS project builds on previous experiments performed in Duncan Sutherland’s lab. In principle, the approach is simple: The surface of the culture wells must provide the adhesive signals that are essential in addition to the signals that they get from each other and the liquid growth medium, in which the cells are grown. The CELPPLUS approach is to place discrete protein nanopatterns on a glass surface, which forms the bottom of each of the culture wells. Depending on the protein nanopatterns, the cells will form different types of adhesions. “When we can control the pattern of proteins on the surface, we also have control of the signals that the cells sense. In this way, we can control how cells behave and thus make them better models for the human body,” explains Duncan Sutherland.

It might sound simple, when phrased like this, but it’s an intricate multi-step process to make the specific protein nanopatterns, and the scale-up to accommodate 96-well plastic culture plates have required much adaption. For instance, the CELPPLUS team has 3D-printed their own custom tools and the process of creating good protein nanopatterns on the large glass substrates that turned out to be more labor intensive than expected.

That said, the CELPPLUS team is well underway. “We have now developed a generic cell culture platform that can be modified to suit basically any disease which can be modelled in cell cultures. The next step is to validate the assay’s potential,” Duncan Sutherland says.

Proof of principle - Mimicking the natural environment of skin cells

As pointed out by Duncan Sutherland, the CELPPLUS assay must be validated now that the team has succeeded in developing a method for nanopatterning the proteins in culture wells. This is where the other CELPPLUS team members come into play. LEO Pharma was industry partner in the project. Among other thing, they provided skin cells, also known as keratinocytes, to be used in the proof of principle study with the new assay.

“In the lab, we have created cell culture plates with protein patterns in three different sizes. We’ve used specific proteins from the keratinocytes’ natural environment in the body to test if they behave similarly to how they would in the body,” tells Duncan Sutherland. Both imaging and sequencing techniques are in play, when the CELPPLUS team evaluates the behavior of the keratinocytes. “When we assess the behavior of the cells, we look at both their appearance and the genes that they express,” says Claus Johansen, who is Duncan Sutherland’s academic collaborator and a molecular biologist working within dermatology. He elaborates: “The cells both look natural and respond to inflammation in the same genes as in our skin. We believe that the CELPPLUS assay will prove very valuable.”

And it seems, in fact, that the CELPPLUS assay is valuable. Currently, the CELPPLUS team is making an effort trying to make the keratinocytes differentiate by changing the protein nanopatterns. When the cells differentiate, they develop into different types of keratinocytes. If they succeed in steering the keratinocytes into further developed cell types, it adds even further possibilities for how to use the CELPPLUS assay.

Taking the CELPPLUS assay to the next level – from open to closed research

The CELPPLUS project is funded by the ODIN network. Therefore, openness is a requirement. All findings from the project must be shared openly with the public, and everyone is free to further mature the results and use them for commercial purposes. “Working in an open project is fantastic for being able to talk about the things we are doing. It’s also great for making new connections,” says Duncan Sutherland.

Making new connections is on the to-do list for the CELPPLUS team. Because the team has developed an assay with broad potential use within different therapeutic areas, a new and closed collaboration with a pharma company is an obvious next step for the team. “When the assay is thoroughly validated, we will approach both pharma companies and cell culture well manufacturers with an aim to establish closed collaborations. It’s our aim for the CELPPLUS assay to help researchers make better and more relevant results. We hope that it eventually can become a standard assay in both research labs and in the drug discovery pipeline,” concludes Duncan Sutherland.