Sweedhart

Separation of weeds during harvesting and hygienisation to enhance crop productivity in the long term (Sweedhart)

BACKGROUND

During the last years the weed pollution of fields has become an increasing problem. Currently, application of herbicides is the pre-dominating method to control weeds. But the existing herbicides become more and more ineffective due to evolution and spread of herbicide resistant weeds. Furthermore, alternatives to design new herbicides seem to be more or less depleted which leads to increasing weed infestation worldwide.

The situation calls for new integrated weed management approaches to avoid increasing weed problems in the future and new methods need to be developed to replace and supplement present methods.

In state-of-the-art wheat-harvesting three different output-streams are generated with modern harvesters: the grain is separated and collected on the harvester.

In addition the harvester chops straw or deposits a straw swath on the field that can be collected some days later. The third fraction is called chaff which contains all other small and light parts from the harvested material like husk and short straw parts as well as including most of the weed seeds.

In current harvesting practices chaff is blown uncontrollably back on the field leading to a wide and homogeneous distribution of the weed seeds.

OBJECTIVE

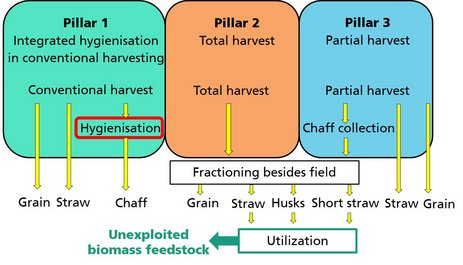

In Sweedhart two principles are investigated to prevent to bring viable weed seeds back to the field:

- A thermal hygienization in-side the harvester is investigated to kill weed seeds.

- The chaff and all harvested weed seeds are collected in a controlled manner and brought off the field. This makes also a new biomass source available.

- Proof-of-concept for hygienisation of weed seeds on the harvester

- Machine adaption of the harvester for improved chaff handling

- Test of the preferred concept by field tests and evaluation of weed reduction potential

- Evaluation of a partial harvest where chaff is collected. Further use (material, feed and energetic) of chaff is investigated as well as potential new innovative applications.

- Evaluation of the concept of a total harvest without separation on the harvester

- Mechanical treatment of harvested material for further purposes

METHODOLOGY

Simulation and prediction of applicable parameters → Test in laboratory scale and check of effectiveness in greenhouse experiments → Transfer to field tests: Valuation → Sweedhart harvest methods → Effectiveness check and evaluation of success

RESULTS AND KEY FINDINGS

The results achieved so far are promising. The basic principles of all concepts have been approved. The realization of the hygienization concept is quite challenging because of the necessary hygienization parameters on the one hand and the geometry of and the conditions inside the harvester on the other hand. The pelletizability of chaff and its applicability as fuel can be recommended.

Thus, a new biomass source is available. Harvested weed seeds can be removed from the field by the Sweedhart measures. Sweedhart investigates the proposed concepts in terms of applicability, sustainability, added value generation and weed reduction potential. The final outcome will be a catalogue that summarizes and rates the measures.

Coordinator:

Dr. Christoph Glasner

Fraunhofer Institute for Environmental, Safety, and Energy Technology UMSICHT, Germany

Email: christoph.glasner@umsicht.fraunhofer.de

Project partners:

- Norwegian University of Science and Technology (NTNU),Norway

- University of Copenhagen, Denmark

- CLAAS Selbstfahrende Erntemaschinen GmbH, Germany

Project period: 05/2016 - 04/2019

Topic: Bioenergy research, Farming equipment and machinery, Waste, by-products and residues management, Plant and Environmental Sciences - Crop sciences, Specialized analytics in the discipline of Biotechnology.

Keywords: agricultural residues, biomass, environmental impact, harvesting, weed management strategies, chaff utilization, pelletizing, logistics of harvested material

Funding: 1.540.000 €

Scientific publications

- Evaluation of New Harvesting Methods to Reduce Weeds on Arable Fields and Collect a New Feedstock

Energies 2019, 12(9), 1688

By Christoph Glasner, Christopher Vieregge, Josef Robert, Johanna Fenselau, Zahra Bitarafan and Christian Andreasen - "Exploiting Waste Heat from Combine Harvesters to Damage Harvested Weed Seeds and Reduce Weed Infestation"

Agriculture 2018, 8(3), 42

By Christian Andrease, Zahra Bitarafan, Johanna Fenselau and Christoph Glasner

- "Evaluation of the process steps of pretreatment, pellet production and combustion for an energetic utilization of wheat chaff"

Front. Environ. Sci., 11 June 2018

by Barbara Dorothe Weiß and Christoph Glasner

Proceedings

Proceedings of the EWRS 2018

- Using exhaust gas from a combine harvester to kill harvested weed seeds

- Seed production and seed shattering of black-grass in winter wheat