Safe and healthy products from farm to fork

The project HO-FOOD aims at developing and implementing a new mild food process and technology to improve the safety and extend the shelf-life of Ready To Eat (RTE) fresh organic products.

In the last decades, increasing demand for fresh fruits and vegetables has been registered in the whole world due to a more widespread consumer attention towards a healthy diet. Fresh fruits and vegetables are rich in macro and micronutrients (minerals, vitamins, polyphenols, dietary fiber, etc.), have a good taste and appearance but they are affected by quick spoilage, mainly caused by microorganisms (bacteria, yeasts, and molds) and oxidative-enzymatic deterioration. When fresh-cut products are used as Ready-To-Eat (RTE) they have a limited shelf life (2-5 days) and current processes have a high risk of cross-contamination due to both naturally present microorganisms and pathogens. Currently available technologies used to increase the safety and shelf life of fresh-like products are still very limited.

University of Padova (Italy), Institute of Agricultural and Food Biotechnology (Poland), Council for Agricultural Research and Economics (Italy), University Ahmed Benbella Oran (Algeria) and Ataturk Central Horticultural Research Institute (Turkey) are part of the project “Innovative high-pressure process to increase the preservation of ready-to-eat Organic food” (HO-FOOD).

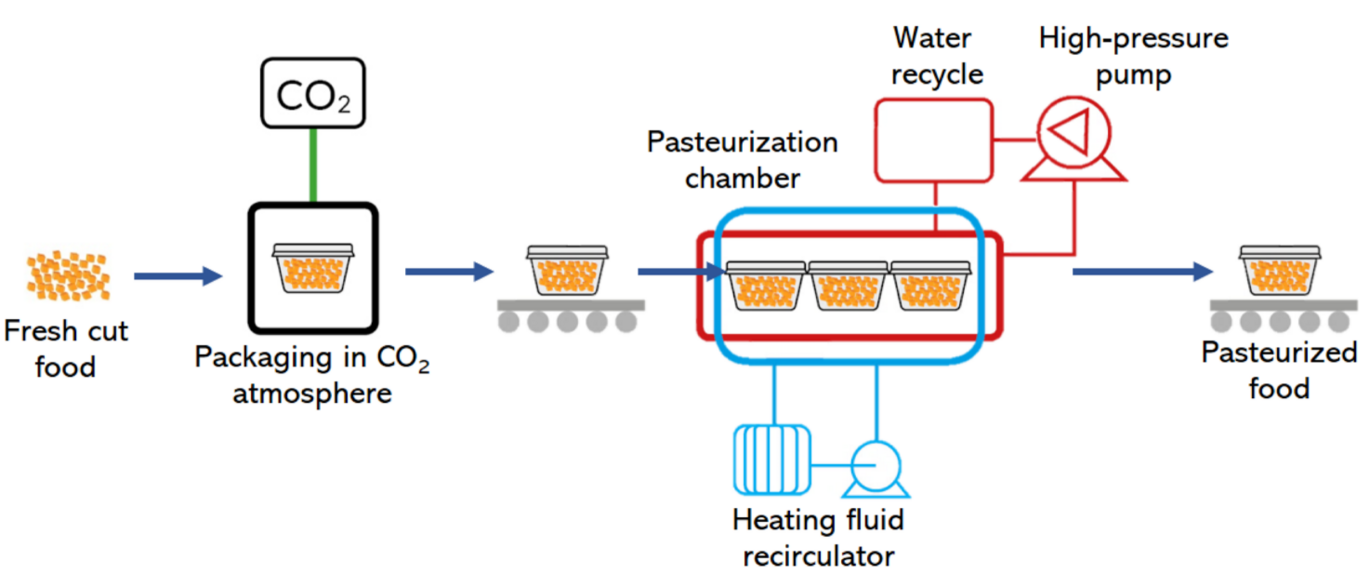

The overall goal of the project is to strongly contribute to addressing the gap of the existing technologies and supporting the local fresh food supply chain by developing a new mild, minimal, and low-cost pasteurization technology for fresh/raw fruits and vegetables as RTE. The technology is based on the method patented by professor Sara Spilimbergo from the University of Padova, schematised in the figure, which has the potential of changing the food chain setup.

The new process will consist in pressurizing the product inserted in Modified Atmosphere Packaging enriched with carbon dioxide (CO2) until reaching supercritical conditions to inactivate microorganisms and enzymes present on the surface and responsible for food spoilage. The process will be efficient against foodborne and well as pathogenic microorganisms and will increase food safety. By using low temperature, sensorial and chemical properties will be preserved, resulting in healthy and palatable food while preserving the phytochemical components of organic foods.

The implementation of HO-FOOD requires expertise from different scientific fields, such as food science, microbiology, chemical engineering, food engineering and economics. The goals of the project will be indeed addressed by fully studying all aspects of the process regarding not only the microbial safety, the quality and bio-accessibility of the selected products, but also by assessing the economic sustainability and environmental impact of the process and by producing apparatuses for its application.

Read more about the project

Website: http://superunit.dii.unipd.it/en/

Social media:

Authors

Sara Spilimbergo; sara.spilimbergo@unipd.it

Alessandro Zambon; alessandro.zambon@unipd.it

Riccardo Zulli; riccardo.zulli@unipd.it

Department of Industrial Engineering, University of Padova

Editor: Karin Ullven / Design: Christine Dilling