Ready To Eat fresh organic products

The HO-FOOD project is working on the optimization of the novel food pasteurisation method for Ready To Eat (RTE) fresh organic products.

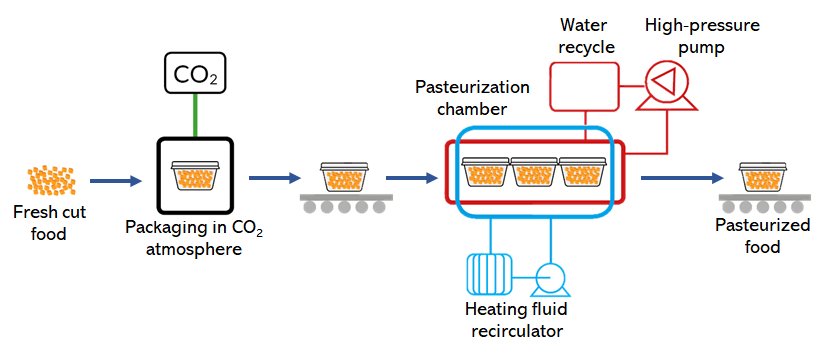

The HO-FOOD consortium is working together to develop a new mild, minimal, and low-cost pasteurisation technology for fresh/raw fruits and vegetables as RTE. The technology is based on the method patented by professor Sara Spilimbergo from the University of Padova, schematised in figure 1, which has the potential of changing the food chain setup.

The new process consists in pressurising the product inserted in Modified Atmosphere Packaging enriched with CO2 until reaching supercritical conditions to inactivate microorganisms and enzymes present on the surface and responsible for food spoilage.

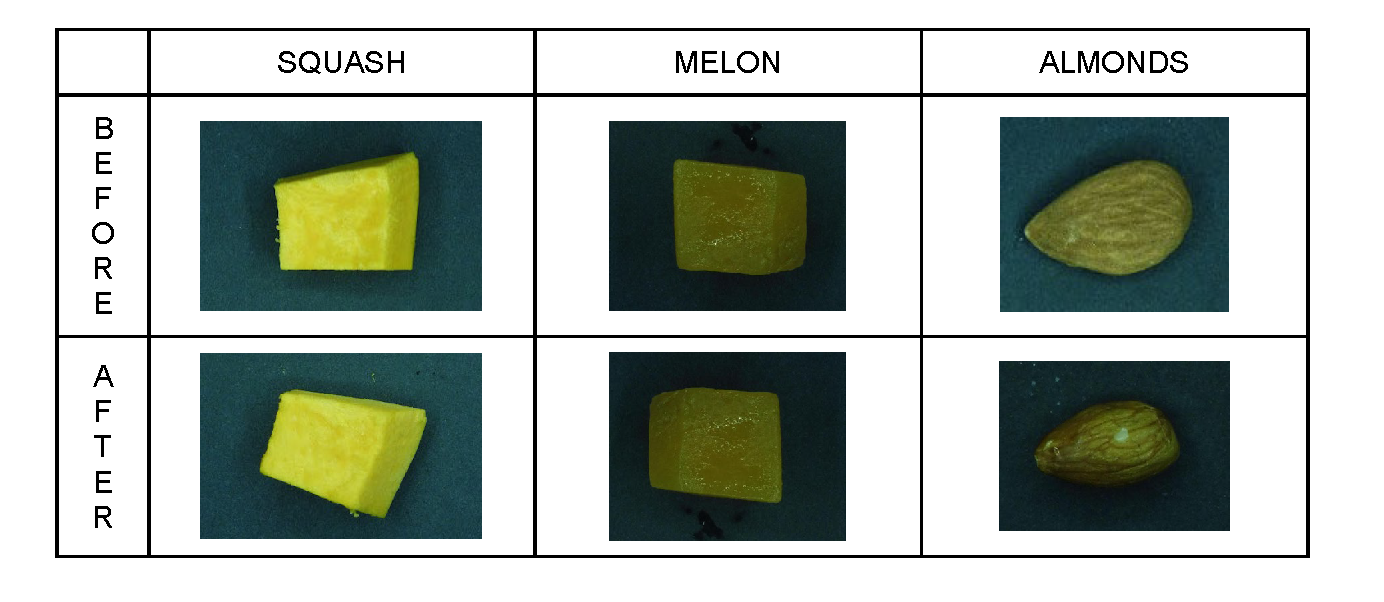

The project firstly aimed at selecting the organic products to be tested considering different aspects, such as seasonality, variety, difficulty of preservation, market potential, geographical area of production and ability to resist high pressure processes. After a first screening, the products have been tested at different processing conditions of temperature, pressure and time, and three products have been selected to be further investigated: squash, melon and almonds (see figure 2, before and after the treatment).

Meanwhile, two sustainable packaging materials have been selected, thanks to the collaboration with international packaging production companies. Two small-scale plants for the application of the process have been designed and fabricated with the aim of being easy-to-use, light and compact, in order to be exploited by the project partners and by small and medium enterprises interested in the technology.

At the moment, the consortium is working on the optimization of the microbial inactivation of the method to select the optimal processing conditions, able to ensure safety and an adequate shelf-life for the three selected products. The first microbial inactivation studies have been carried out on a synthetic matrix, where different microorganisms have been inoculated, allowing to study the effect of the process conditions and the kind of microbiota present on the products. The tests will now be carried out on the natural matrices to assess the effect of the different product characteristics on the microbial inactivation of both the natural flora and some inoculated pathogenic (or surrogate) bacteria.

The optimised conditions will be then adopted to study the products from the other points of view: quality, sensorial, nutritional, and bio-accessibility characteristics. Moreover, the economic and environmental sustainability of the process will be studied and compared with other technologies that are already adopted in the food industry.

Authors

Sara Spilimbergo - sara.spilimbergo@unipd.it

Alessandro Zambon - alessandro.zambon@unipd.it

Riccardo Zulli - riccardo.zulli@unipd.it

Website: http://superunit.dii.unipd.it/en/

Social media: https://www.linkedin.com/company/superunit-co2/

https://twitter.com/SuperunitCO2

Editor: Karin Ullven, EPOK / Design: Christine Dilling, ICROFS