Project outcomes

Results from WP2

- Use of innovative packaging technologies

To increase the very short shelf-life of fresh berries and reduce waste, especially in the household, food service and retail sectors the use of Modified Atmosphere Packaging (MAP) technology as an alternative to conventional packaging, has been evaluated.

To increase the very short shelf-life of fresh berries and reduce waste, especially in the household, food service and retail sectors the use of Modified Atmosphere Packaging (MAP) technology as an alternative to conventional packaging, has been evaluated.

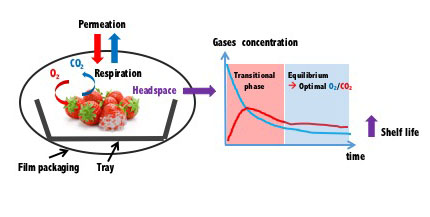

In passive MAP, the product creates by its own the modified atmosphere in its close surrounding thanks to its active respiration metabolism.

In active MAP, modified atmosphere is created by flushing the desired gas mixture and/or using absorbers and/or emitters (e.g. O2 scavengers, CO2 emitters, etc.).

Virtual MAP modelling tools can be used to determine the gas packaging permeabilities suitable for a given fresh produce and geometry (mass of food, volume of package), which could not be rapidly and simply achieved by using only empirical, experimental storage tests. Once these permeabilities are known, the corresponding packaging materials could be identified in dedicated databases.

This approach was conducted in the case of strawberries with the idea to identify bio-based commercial materials for the packaging of organic berries. Gas permeabilities suitable for strawberries are quite high and could not be achieved using commercial oil-based either bio-based packaging material without micro-perforated the plastic film or unreasonably increase the ratio volume of package onto mass of packed strawberries.

The second strategy was used to validate the interest of passive MAP: 100g of strawberries were packed in LDPE pouches big enough to ensure the establishment of the suitable modified atmosphere without risking anoxia which would be detrimental for the product. Shelf life of the product was determined as a function of time on the basis of spoilage (surface of rotted strawberries) evaluation and in conditions (time-temperature history) mimicking the commercial storage conditions.

Passive MAP permitted to significantly increase shelf life of one full day if compare to the benchmark (i.e. 4d instead of 3d if no MAP). Higher shelf life gains are expected by using active MAP, for instance, by the addition of O2 scavengers in the pack for reducing the transitional phase before optimal atmosphere establishment and moisture absorber to control water vapour transmission in the MAP system.

Results from WP3/WP4

- Identify processing solutions to enhance the safety and overall quality and nutritional value of organic berries and products

To increase the commercial value and reduce waste it is reasonable to process seasonal and perishable berries into added value products. Berries can be dried and milled into stable and convenient powder products, which can be further used as ingredients in the food industry (bakery fillings, ice cream and yoghurt flavouring, extruded snacks/cereals and more).

To increase the commercial value and reduce waste it is reasonable to process seasonal and perishable berries into added value products. Berries can be dried and milled into stable and convenient powder products, which can be further used as ingredients in the food industry (bakery fillings, ice cream and yoghurt flavouring, extruded snacks/cereals and more).

The choice of processing methods and conditions highly affects the characteristics of fruit and vegetable products. Therefore, process design is a valuable tool to achieve high quality products; the functionality of berry powders can be tailored by adaptation of the processing conditions.

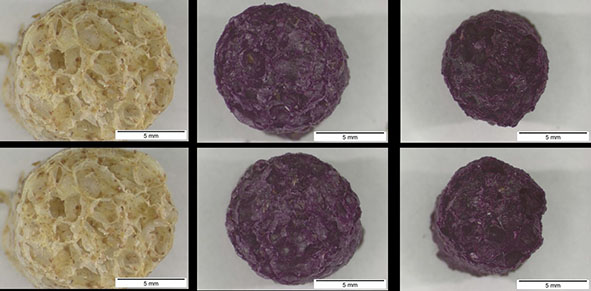

Drying studies have been focused on powders made from bilberries (which are rich in anthocyanins), but the same methodology can also be used for other berries. Mechanical pre-processing, various drying technologies, and post-drying fractionation are evaluated in terms of powder characteristics such as solubility, flowability and phenolic content retention.

Furthermore, powder from bilberry press cake has been successfully added during extrusion of puffed, cereal based extruded snacks. The use of side streams from the berry processing industry enables production of environmentally sustainable and value added products in line with organic production principles.

Application of mild technologies on berry fruits

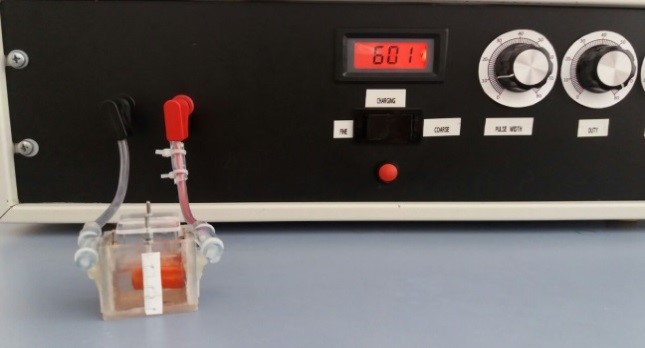

Osmotic dehydration (OD) was used in order to obtain the semidried fruit products. Since OD is a time requiring process, Pulsed Electric Fields (PEF) was also evaluated as additional process to accelerate the tissue dewatering, as a pre-treatment of kiwifruit and strawberries prior the OD process.

The application of PEF as a pre-treatment of the OD in both fruits increased the water mass transfer compared with samples that have not been pretreated. In particular, in kiwifruit, the PEF intensity of 100 V/cm was identified as an optimal process parameter to obtain both higher mass transfers during OD and the fruit microstructure and cell viability preservation.

Concerning the strawberry samples, the results showed that PEF coupled with OD had a greater effect on mass transfer phenomena and water redistribution mainly when sucrose solution was used for OD treatment compared to trehalose solution. Strawberry fruits treated with low PEF voltage better maintained their colour. However, all the PEF-OD treated samples were softer than the untreated ones.

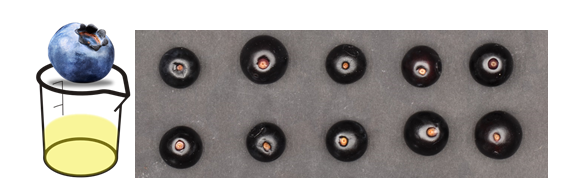

Effect of different edible film on blueberry quality

The application of edible coating seems to be a promising technique to increase the shelf-life of fruits and their nutritional values. It represents an alternative way of conservation, because of their ability to reduce moisture, solute migration, respiration and transpiration rate; to maintain firmness and overall product quality during storage.

The effectiveness of three different types of edible coatings (sodium alginate, pectin and sodium alginate + pectin) in improving the shelf-life of blueberry fruits was investigated.

Obtained results showed that the application of all kind of applied coating improved the firmness of blueberries. Coated samples did not show significant difference in weight loss, pH, soluble solid content and dry matter. Changes in the surface reflection properties in the coated blueberries induced a general lower lightness and more intense blue hue colour than the control sample. Edible coating reduced the growth kinetics of yeasts and mesophilic aerobic bacteria.

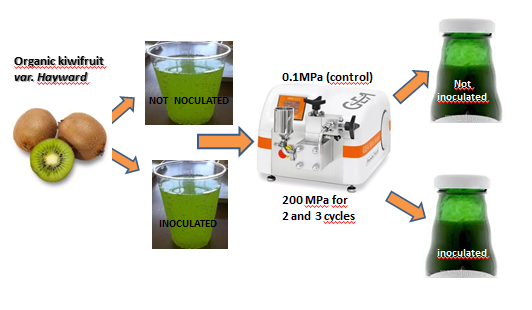

High pressure to improve safety, shelf-life and functionality of organic Chinese gooseberry juice

Juice samples have been treated by different HPH treatments in order to define the processing conditions to increase their shelf-life.

Challenge tests were carried out to understand the inactivation dynamics by HPH and the potential microbial re-growth in juices during storage at various conditions.

Both pathogenic (L. monocytogenes, E.coli) and spoilage (S. cerevisiae Z. bailii, and Lb. plantarum) microorganisms were inoculated in Chinese gooseberry juice and their inactivation and re-growth dynamics studied in relation to the pressure applied. HPH increased the death kinetics of the pathogenic L. monocytogenes, which at the pH detected has no re-growth potential. Spoilage microorganisms were reduced enough by HPH to achieve a shelf-life of >40 days at cold storage (200 MPa for 3 passes) or 10 days at room temperature (200 MPa for 3 passes).

HPH treated gooseberry juice maintained its green colour and no decrease in total phenolic content was detected. The HPH treatment resulted in higher viscosity than control juice.